联系-新盛公司客服中心【微-64881330】

新盛公司官方游戏网址 www.xs8617.com 联系-新盛公司客服电话-【134-0888-8125】-企鹅微信同步-【64881330】新盛公司客服24小时在线,【公司直属客服】【公司直属开...

Control Method

I. Introduction

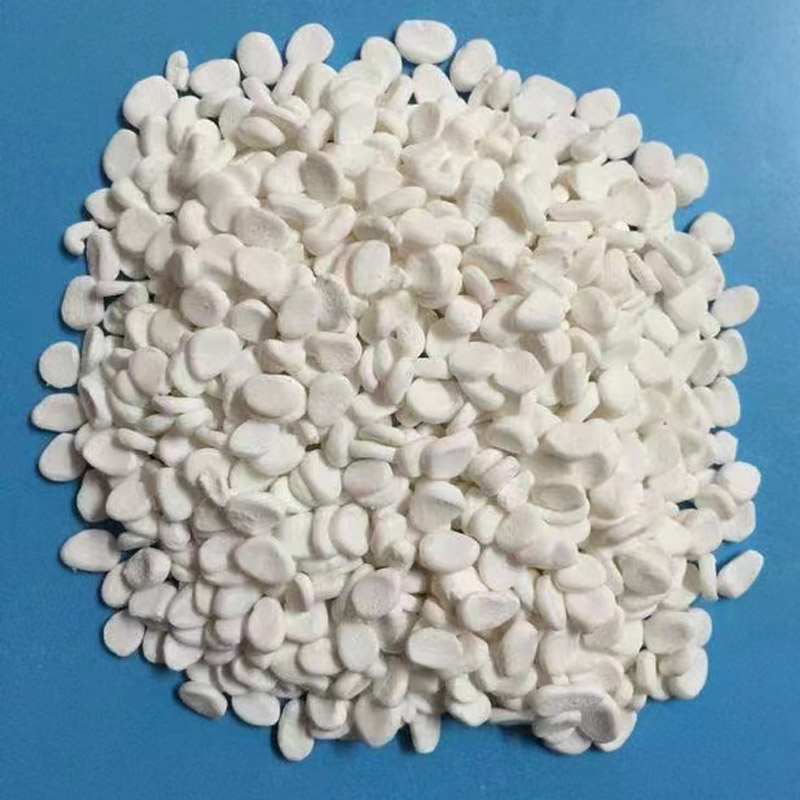

Name: Nylon Reinforced Flame Retardant Masterbatch

Model: PA602

Appearance: White spherical granules

Addition Level: 22% (for 3.2mm thickness) or 24% (for 1.6mm thickness)

Environmental Standard: ROHS

Flame Retardant Rating: UL94 V-0

Application Scope: Flame retardancy for reinforced PA6, etc.

II. Advantages and Strengths

Utilizes an eco-friendly bromine-antimony flame retardant system with high efficiency.

Offers good thermal stability, higher whiteness, and cost-effectiveness.

Features easy dispersion, UV resistance, and non-blooming.

III. Specifications

Item | Quality Indicator |

Active Flame Retardant Content % | ≥ 85 |

Density g/cm³ | 2.10 |

Moisture Content % | ≤ 0.1 |

Twin-Screw Processing Temperature °C | ≤ 220 |

Twin-Screw Rotation Speed rpm | ≤ 300 |

Injection Molding Temperature °C | ≤ 255 |

IV. Appendix: Application Examples

1-1. Formulations and Typical Physical Properties:

No. | A | B | C | D | E | F | Ref 1 | Ref 2 |

Component/Property | ||||||||

PA6 + 30% GF | 78 | 78 | - | - | 78 | - | - | - |

PA66 + 30% GF | - | - | 70 | 79 | - | 81 | - | - |

DBDPE | 14 | - | - | - | - | - | - | - |

BPS | - | - | 20 | - | - | - | - | - |

Sb₂O₃ | 4 | - | 6 | - | - | - | - | - |

Additives & Others | 4 | - | 4 | - | - | - | - | - |

PA602 | - | 22 | - | - | - | - | - | - |

PA600 | - | - | - | 21 | 22 | - | - | - |

PA600AC | - | - | - | - | - | 19 | - | - |

UL94 (1.6mm) | V0 | V0 | V0 | V0 | V0 | V0 | - | - |

Notched Impact (23°C) kJ/m² | 8.0 | 16.5 | 11.0 | 12.2 | 13.5 | 13.5 | 17.5 | 14.1 |

Tensile Strength MPa | 160 | 136 | 130 | 106 | 121 | 136.4 | 163 | 148 |

Elongation at Break % | 2.0 | 4.1 | 3.0 | 2.4 | 4.1 | 2.46 | 3.2 | 1.2 |

Flexural Strength MPa | 190 | 195 | 175 | 175 | 158 | 200.6 | 219 | 233 |

Flexural Modulus MPa | 7000 | 6825 | 5500 | 6704 | 5907 | 7149 | 7822 | 8650 |

HDT °C | ≥210 | ≥215 | ≥250 | ≥240 | ≥220 | ≥240 | ≥250 | ≥250 |

1-2. PA6 Injection Molding Process

Drying Conditions: Use a dehumidifying dryer at 80-90°C for 2-3 hours.

Injection Molding Temperature Settings:

Nozzle: 250°C

Zone 1: 255°C

Zone 2: 250°C

Zone 3: 245°C

The test data and processing parameters above are for reference only and do not serve as a formal quality guarantee. Masterbatch formulations can be customized based on specific customer requirements.

V. Applicable Products

Widely used in power tools and their components, various mechanical instruments, electronic and electrical appliances, connectors, terminal blocks, and other products.

VI. Packaging / Storage

25 kg/bag, paper-plastic composite packaging.

Transport as general chemicals.

Store in a dry, cool place. Protect from moisture and avoid direct sunlight.

VII. Frequently Asked Questions (FAQ)

Q: Can it plasticize well at 210°C in twin-screw extrusion?

A: Yes. After being encapsulated in a carrier to form the masterbatch, the flame retardant's melting point decreases, allowing easy melting with glass-filled PA6 and lowering the overall plasticizing temperature. It plasticizes very well at 210°C, and the maximum processing temperature can be up to 230°C.

Q: For PA6 with 30% glass fiber, what addition level is needed for UL94 V-0? What about for passing 850°C Glow-Wire?

A: For PA6 + 30% GF, add 20% to achieve V-0 at 3.2mm thickness. Add 22% to achieve V-0 at 1.6mm thickness and simultaneously pass the 850°C Glow-Wire test.

Q: For pure PA6 resin, what addition level is needed for UL94 V-0 and to pass 850°C Glow-Wire?

A: For pure PA6 resin, add 24% to achieve V-0 at 1.6mm thickness and pass the 850°C Glow-Wire test.

Q: What is the most important precaution when using this masterbatch?

A: The heat resistance of any flame retardant is limited. For this masterbatch in PA6 GF materials, key points are: 1) Processing temperature: keep twin-screw temp ≤ 230°C; 2) Rotation speed: keep twin-screw speed ≤ 300 rpm. This yields products with color closest to natural, best properties, and lowest cost. Also, keep injection molding temperature ≤ 255°C.

Q: For direct injection molding with PA6 GF material, what drying temperature is recommended for the masterbatch?

A: It's recommended to mix the masterbatch with the base resin uniformly and then dry at 90°C for 3 hours. Higher temperatures may cause the carrier to become sticky, leading to agglomeration or even discoloration.

Special Note:

The optimal addition ratio varies depending on the base material. Small-scale trials are essential before full production.

OnlineMessage

CN

CN EN

EN